Troubleshooting: Partial Gel in Cold Process Soap

In the Modern Soapmaking Troubleshooting Talk series, we explore various soap making problems and find out what went wrong plus share some tips and tricks to put the smack down on issues that pop up.

Today we’re talking about…

Partial Gel in Cold Process Soap

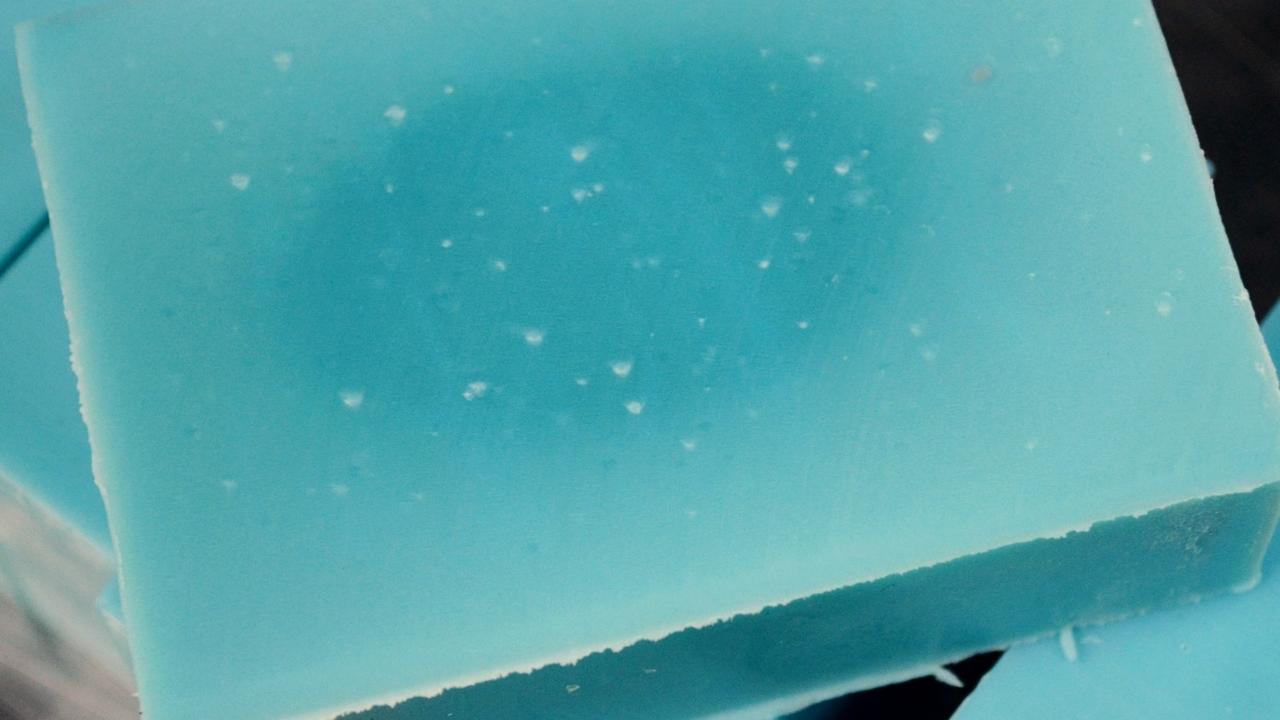

What is partial gel? The central area in the soap is darker and more translucent than the outer edges of the soap.

What causes partial gel? Saponification is an exothermic reaction, which means it releases heat. If there is enough heat during saponification, you'll see a gel phase which is when the middle of the soap mass starts to look like translucent jelly.

I've temped a lot of soaps during gel and have seen temperatures up to 220° F. Wowsa!

Soap that has gelled tends to have a more translucent finish and a darker (and sometimes, more saturated) color. Ungelled soaps are more opaque and tend to have a duller final color.

If the soap cools off before the gel phase reaches the edges of the mold, the final soap will have a partial gel.

How do I prevent partial gel? A partial gel can be prevented by either forcing a full gel phase or by avoiding the gel phase altogether.

To force a full gel phase, try:

- Soaping at 110° F to 140° F, depending on your formula and additives. (Be careful with additives that accelerate trace!)

- Invert a cardboard box over the mold and wrap it with a fabric that insulates well, such as wool or felt.

- Oven process the soap by placing it in an oven set to 170° F for about 15 minutes. Turn off the oven. Leave the soap in the oven until saponification is complete. (Don't let heat escape the oven by opening the door to peek!)

- Place the soap mold on a heating pad or a seedling heat mat during saponification.

To avoid a gel phase, try:

- Soaping at room temperature, depending on your formula and additives. (Be careful with hard oils or additives that have a low melting point, such as cocoa butter, shea butter, stearic acid or beeswax!)

- Place the soap mold in an refrigerator or freezer, depending on the additives used. (A refrigerator is usually enough, except in the case of additives that heat up like honey or milks.)

A 25 lb slab of soap with partial gel

Is the soap usable? Of course! A full gel phase is not required for saponification to complete. Heat is a catalyst of saponification, and will make the soap harder quicker.

A partial gel or ungelled soap may take longer to saponify, but as long as it's formulated correctly, it poses absolutely no issues with usability.

Can soap with partial gel be fixed? If you notice a soap cooling off before a full gel phase, you can try one of the recommendations above to force gel phase.

You can also sometimes oven process a partial gelled soap (in the mold!) within 24 hours, if you discover it has a partial gel. This can take upwards of 30 to 45 minutes in the oven at 170° F.

Keep an eye on the soap so you don't dry it out or overheat it. Watch for telltale signs of overheating like cracking on the top of the soap or any expansion of the soap in the mold.

Want to snag weekly advice on building a successful soap biz directly in your inbox?

Of course you do! Sign up for our newsletter below for more tips and tricks to make bank in your biz.